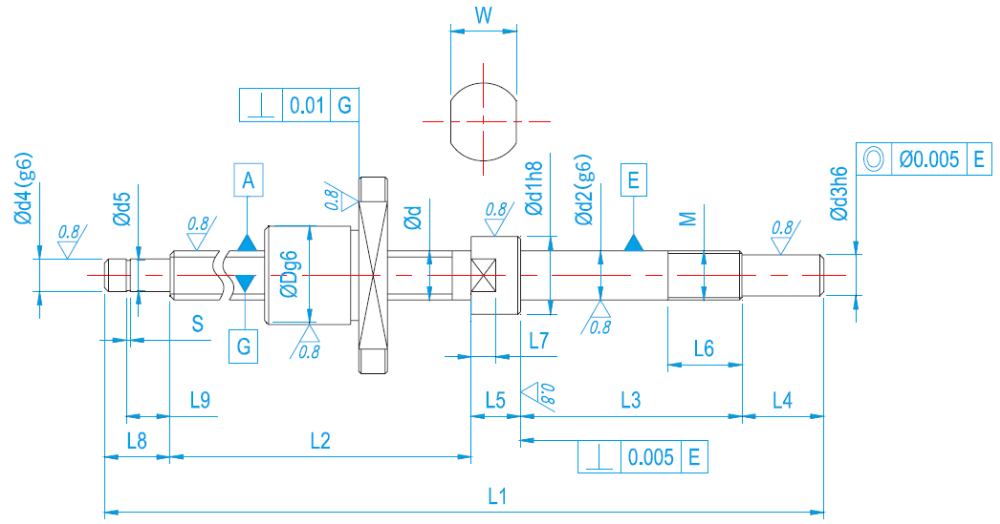

Material: GCR15 or Stainless Steel

Performance: high-precision

Type: Milled Thread

Nominal Diameter: 10mm

Lead: 3mm

Accuracy grade: C3, C5, C7

Other characteristics: Smooth running

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.