Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: KK5002

Brand: WKT

Place Of Origin: China

Status: New

Service System: Overseas Service Center Available

Applicable Industry: Construction Works, Manufacturing Plant, Other

Out-of-warranty Service: Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): United Kingdom, South Korea

Showroom Location (in Which Countries Are There Sample Rooms Overseas): United States, Colombia, South Africa

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor, Bearing

Supply Ability & Additional Information

Packaging: wooden package or cartoon

Productivity: 2000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: SuZhou

Supply Ability: 2000pcs/month

Certificate: IATF16949

Port: ShangHai

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW,FAS

Product Description

|

Main Features

1. Products Stock

2. Low Cost

3. Low Noise

4. Reliable Quality

5. Years of Experience

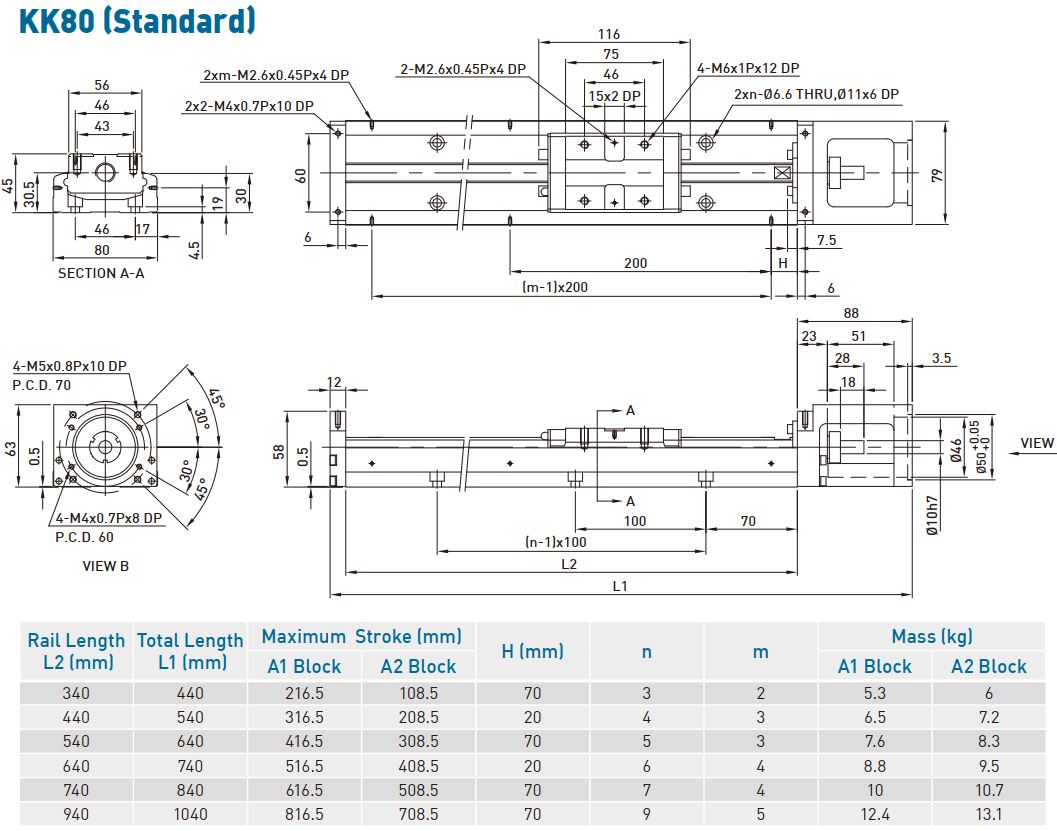

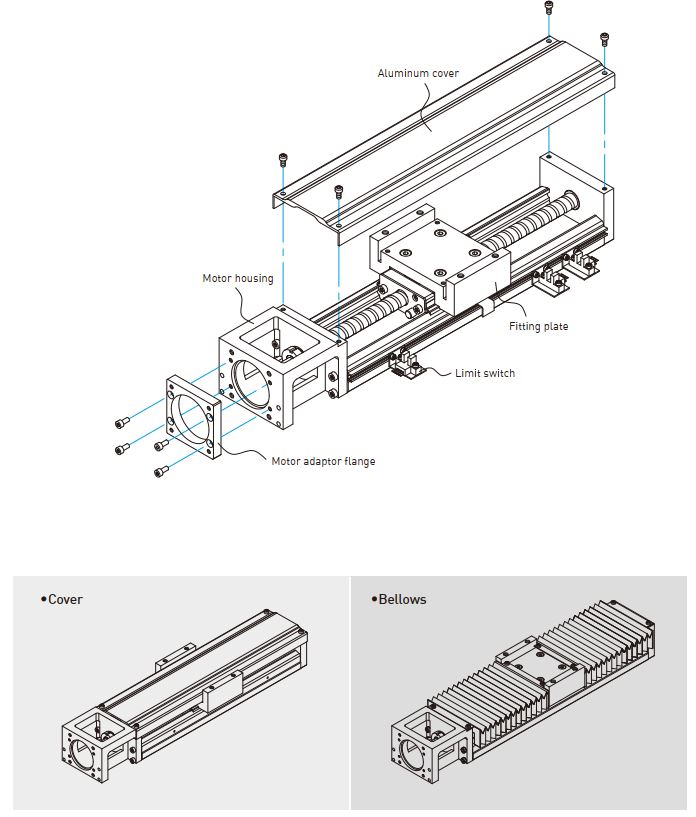

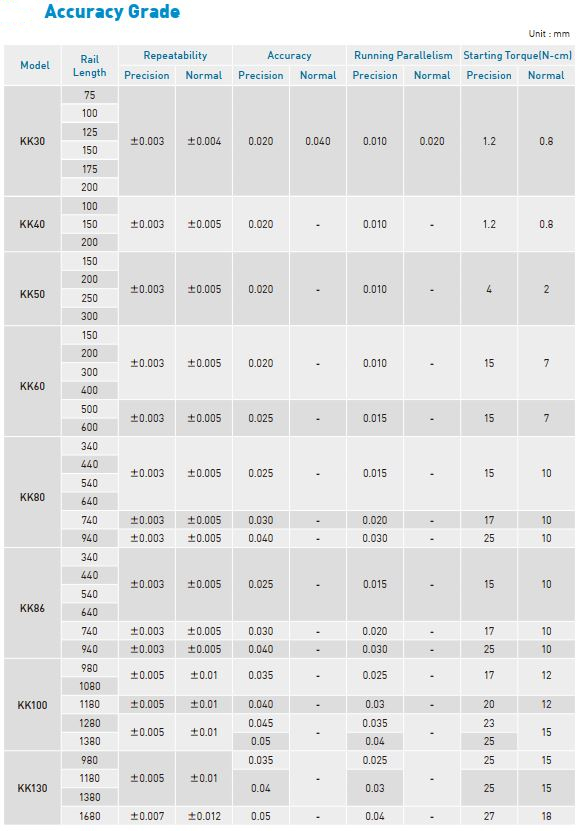

Name: Linear Module

Brand: WKT

Original: Suzhou, China (Mainland)

Packaging Details:

In cartons or Wooden cases upon your requirement

For samples:

we have DHL, FEDEX VIP account, so the shipping freight will be much cheaper after discount.

For bulk order:

we have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

Port:

Shanghai

Lead Time:

7-15 days

Why choose Screwtech

We Screwtech is a professional manufacturer of Ball Screw,Lead Screw,Stepper Motor,Linear Guideway,AKD-Support for ball screw,Linear Bearing for more than 15 years

1. We can offer you products of high quality with economic price

2. We can design and produce customized products upon your requirement

3. We can produce the same size as HIWIN, TBI, PMI, and THK.

Our Business Extent

1. We have business rlations with clients both domestic and abroad.

2. With the high quality,good service as well as reasonable price.

3. we've obtained large numbers of customers from Europe, USA, Canada, Africa, Australia, Korea and so on.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.