Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

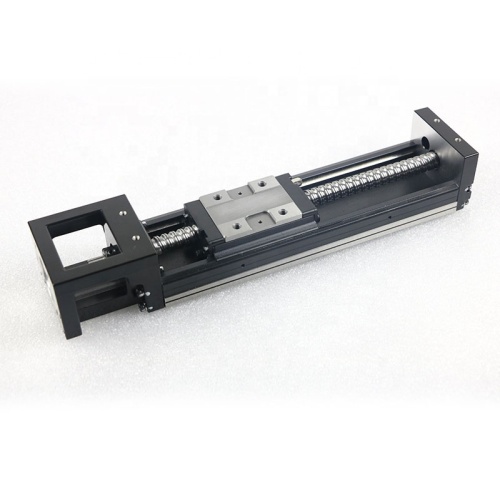

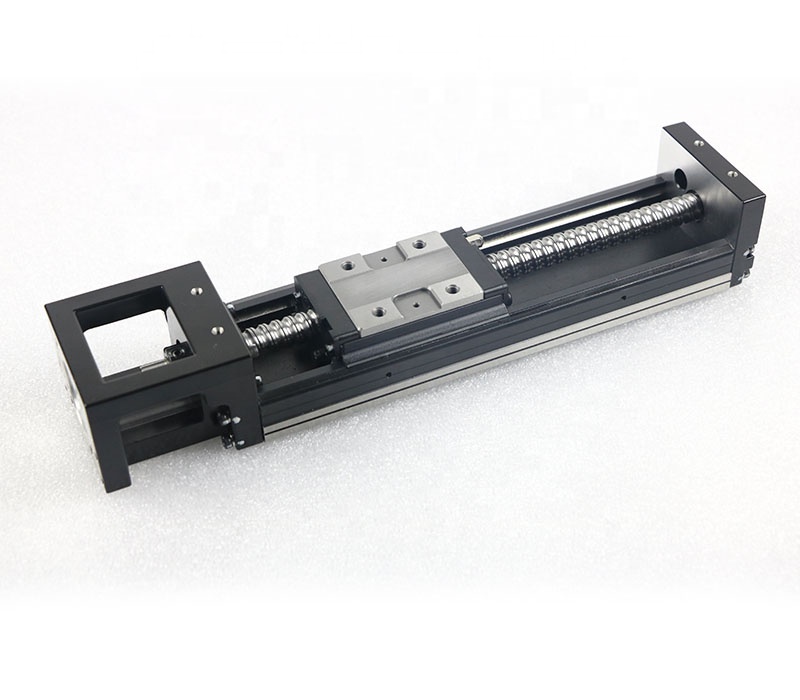

Model No.: KK8620

Brand: WKT

Place Of Origin: China

Status: New

Service System: No Overseas Service Provided

Applicable Industry: Manufacturing Plant, Construction Works, Other

Out-of-warranty Service: Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): United States, Argentina, Kyrgyzstan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): United States, Colombia, Japan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Bearing, Pressure Vessel

Supply Ability & Additional Information

Packaging: wooden package or cartoon

Productivity: 2000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: SuZhou

Supply Ability: 2000pcs/month

Certificate: IATF16949

Port: ShangHai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,Express Delivery,EXW,CIF,FAS,FCA,CPT,CIP

Product Description

CNC machine tools, semiconductor equipment, automation equipment, Medical Equipment, petroleum Machinery, precision mesuring instruments, mechanical arm, laboratory equipment, aerospace, printing machinery, pharmaceuical packaging machinery,enery enterprises, beverage machinery, food machinery and other fields.

Synchronous belt type:

The working principle of the synchronous belt type is: the belt is installed on the drive shaft on both sides of the Linear Module, which is used as the power input shaft, and a slider used to increase the equipment workpiece is fixed on the belt. When there is input, the slider is moved by driving the belt.

Generally, the synchronous belt type linear module is specially designed, and the elasticity of the belt movement can be controlled on one side, which is convenient for the debugging of the equipment during the production process.

Synchronous belt linear modules can choose to increase the rigidity of the linear module according to different load needs. Linear modules of different specifications have different upper load limits.

The accuracy of the synchronous belt linear module depends on the quality of the belt and the processing process in the combination, and the control of power input will also affect its accuracy.

Screw type:

1. The Ball Screw is an ideal product that converts rotary motion into Linear Motion, or converts linear motion into rotary motion. The ball screw is composed of a screw, a nut and a ball. Its function is to convert rotary motion into linear motion, which is a further extension and development of ball screws. The important significance of this development is to change the Bearing from rolling motion to sliding motion. Because of its low frictional resistance, ball screws are widely used in various industrial equipment and precision instruments. High-precision linear motion can be achieved under high load conditions.

2. Linear guides, also known as slide rails, linear guides, and linear slides, are used in linear reciprocating motion applications. They have a higher rated load than linear bearings, and can bear a certain torque at the same time to achieve high precision under high loads. Linear motion. Structure, high precision; precision-grade guide rail plate,

3. Aluminum profile sliding table has beautiful appearance, reasonable design, good rigidity and reliable performance. It is an ideal basic power component for modular machine tools and automatic lines. It has good dynamic performance. The sliding table has high rigidity, small thermal deformation, and feed stability. High, so as to ensure the actual accuracy under the processing state (under load).

Linear motor module type:

The linear motor module is a transmission device that directly converts electrical energy into linear motion mechanical energy without any intermediate conversion mechanism. It has the advantages of simple structure, convenient realization of long stroke, high acceleration, fast response, high precision, etc., and the highest repeatability positioning accuracy is ±0.001μm.

Level of Precision

Maximum Speed

● Products Stock

● Low Cost

● Low Noise

● Reliable Quality

● Years of Experience

Remark

The marked price in the page is not the authentic transaction value. Because the category of screw's products belongs to customized products, the actual price should be given corresponding discount by products' specifications and order quantity.

Name: Linear Module

Brand: Screwtech

Original: Shandong, China (Mainland)

Positioning: 0.010 mm

Start Force: 4 N-Cm

Ball Screw Lead: 2 mm

Basic Static Rated Loading: 2910 N

MP : 116/545

Mr : 222/444

Repeat Positioning: +/- 0.003 mm

Motion Accuracy: 0.010 mm

Ball Screw Dia: 8 mm

Basic Dynamic Rated Loading: 1813 N

Allowed Static Moment: MP/My/Mr

Specification: 410*120*120 mm

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

*Feel free to contact us if you have any questions

Packaging Details:

In cartons or Wooden cases upon your requirement

For samples:

we have DHL, FEDEX VIP account, so the shipping freight will be much cheaper after discount.

For bulk order:

We have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

Port:

Shanghai ; Qingdao

Lead Time:

10~30 day

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.