Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

SCTEWTECH Ball Screw measuring Geometric Tolerance based on screw central axis, below is measuring process:

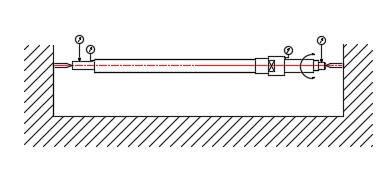

Using a qualified deflection instrument (or machine tool with a center). Withstanding two ends of the screw by center, so that the screw is supported on the deflection instrument or machine tool smoothly. The magnetic dial seat of the dial indicator is attracted On the surface of the deflection instrument or the machine tool guide rail. At the same time, the probe of the meter head should be at the angle of <30° with the surface to be measured, and touch the measurement part; rotating dial makes the pointer to 0, while rotating the screw, Reading the dial indication. During a rotation period, the scale within the range of the dial pointer's left-right deflection is the measured data.

This method can measure the runout of any outside surface of the screw and the central. As shown below

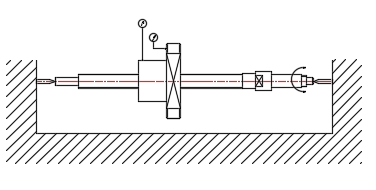

The perpendicularity of the central axis and the end surface of the nut (or flange assembling surface)

Using a qualified instrument (or machine tool with a center), Withstanding two ends by center, so that the screw is supported on the deflection instrument or machine tool smoothly. See the below drawings, measuring nut`s external diameter runout, attaching the magnetic dial base of the dial indicator to the surface of the deflection instrument or the machine tool guide rail, at the same time, the probe of the meter head is lightly touched on the measurement position in an attitude with the angle of <30; Rotating the dial makes pointer to 0, while rotating the screw (there is no relative movement between the screw and nut), reading dial indication. Within one rotation period, the scale left and right deflection of the dial pointer is the measured value; if measuring nut`s end face runout, the dial indicator must be installed on the base of the height ruler which can be adjusted manually. The base of the height ruler is installed on the surface of the guide rail. Put meter head vertically on screw nut end surface, rotating hand to make dial indicator a vertical motion. The the scale within the range of the dial pointer deflection is the measured data.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.