Ball Screw Application in CNC machine and some special Machinery: In order to improve the service life and accuracy of the Lead Screw, sometimes choose hardened treatment, by means of grinding, then get the precision. The ball screw have the characteristics of high positioning accuracy, long service life, low-emission and can reach high-speed forward and reverse transmission, it has become one of the important components in the positioning and measurement system of precision technology industry. Ball Screw is a steel ball that moves between the nut and the screw, converts the traditional sliding contact into rolling contact, and then change the steel ball rotating movement to linear movement. So how can we keep the ball screw in high precision during the working. When the screw vibrates at a fixed Angle, it will induce the terrible torque. This movement causes vibration torque, which is difficult to completely eliminate even use extremely precise parts. However, this torque can be reduced to a minimum by using a Goethe arch instead of a circular ball groove or by reducing the stiffness of the ball screw. The Goethe-type arch has a deeper and better circulating V-shaped section 2) Because incorrect reassembly is easy to lose the function of the ball screw, therefore hope customer don`t reassembly by yourself. Return the product to company and can be repaired for a fee. 3)Ball screw shaft or nut sometimes fall off due to its own weight, please be careful not to hurt. It will lose function If accidentally dropped, the injury of the track or the damage of the circulating parts. At this time, please return the product to our company, let`s make paid inspection. 4)For example, if damage the deflector, outer diameter, scars in track and so on, it will lead to poor circulation and loss function.

How to maintain the accuracy of the ball screw:

Ball screws are usually used in high precise positioning situations. High mechanical efficiency, low transmission torque and almost zero axial clearance make ball screws as an important device for tool positioning and aircraft aileron drive. However, resistance and heat generated by continuous operation can cause a lot of friction and positioning errors.

Increase friction in the ball screw also improve torque and opposite affect positioning accuracy. When compressed the steel ball between the screw and nut, generating the wedge effect is a potential source of friction. In the forward rotation, the steel ball squeezed against the nut; in the reverse rotation, the ball steel squeezed against the screw shaft. Cause the sliding friction coefficient is much larger than the rolling friction coefficient (static state 0.1 ~ 0.3; Rolling 0.001 ~ 0.003), the wedge effect greatly increase the torque.

When combine use the two ball screw nuts, they are usually separated by gaskets, and the pre-loading is determined by the thickness of the gasket. The torque of the ball screw can be reduced by replacing the solid gasket of butterfly spring, which allows axial deformation and thus reduces extrusion. Another major source of drag is the friction between adjacent balls, this can be reduced by removing several balls or replacing some of them with isolated balls (i.e. balls with gaps). With these methods, the torque generated by friction can be reduced up to 30%. The same method is also effective in reducing the friction between the steel ball and its raceway.

In order to minimize friction, the isolating and carrying balls should mutually exchanging. However, certain load and rigidity requirements should request one isolated steel ball per three Bearing steel balls. The isolated steel balls with a smaller diameter than the bearing one act as idlers, they are rotating in the opposite direction of the bearing steel ball and reducing contact friction. But the bad result is decreasing workload if use some isolating steel ball. It should compensate by reduce the workload or increase the ball screw size. The friction from lubrication also increases the torque, especially at high speeds, most of ball screws are used at speeds well below 5 m/min. However, modern machine tools require speeds over 10 m/min, even some systems request speeds up to 30 m/min. The minimum resistance of lubricant depend on the axial rotation speed of the ball screw. Generally speaking, the speed is below 500 RPM or the moving speed is 3 meters/time, and the grease is the best lubrication. At this lower speed it is mainly boundary lubrication. Over 500 RPM should choose oil film lubrication, oil is the best lubricant.

The reduction of positioning accuracy for thermal expansion is not only caused by friction heat of the steel ball movement , but also by the mechanical running heat of factors such as hydraulic fluid, electric motor, gear box and so on. If there is deformation on the guide rail or lathe, it is impossible to obtain high accuracy, even though can prevent the rise of the temperature.When analysis the accuracy, the heat from all such heat sources must be taken into account

High workloads is one of the biggest potential reason when calculating the heat generated by the ball screw itself. Usually, the work load is about 3 times as much as jacking force. The greater load must be compensated by increasing the size of the ball screw device or by greater lubricant cooling capacity. One method to compensate the thermal expansion is applied a pre-loading to the ball screw. This is achieved by end machining the lead screw shaft and get negative tolerance dimensions. It can shortened the pitch, Ball Screw Nut is compressed during assembly. The screw expansion device works normally at the operating temperature.

At extremely high temperatures, installed separate cooling system into the ball screw, spray air or oil mist on the screw shaft. Usually, air cooling is more efficient and with lower wast. Cooling also can be carried out by passing the pressure water through the hollow ball screw, the temperature of the ball screw hardly rises with such a system.

The correct usage of ball screw:

1)Please don`t remove the ball screw by yourself. Otherwise, it is easy to let dust in it, which reduces the accuracy or happen function failure.

Protection of ball screw:

The lubricant can improve abrasion resistance and transmission efficiency. Lubricants are divided into oil and grease. Lubricating oil have 90~180 turbine oil or 140 spindle oil. Grease can be choosed weird base grease. The grease is added into the housing space of the threaded raceway and mounting nut, while the lubricating oil is injected into the nut oil holes for the nut housing.

As long as avoided abrasive particles and chemically active substances into inside, the ball screw and other motion part can be considered as normal work. However, if the dust fall into raceway, or use dirty lubricating oil, it will not only affect the normal operation of the ball, but also extremely increase the abrasion.

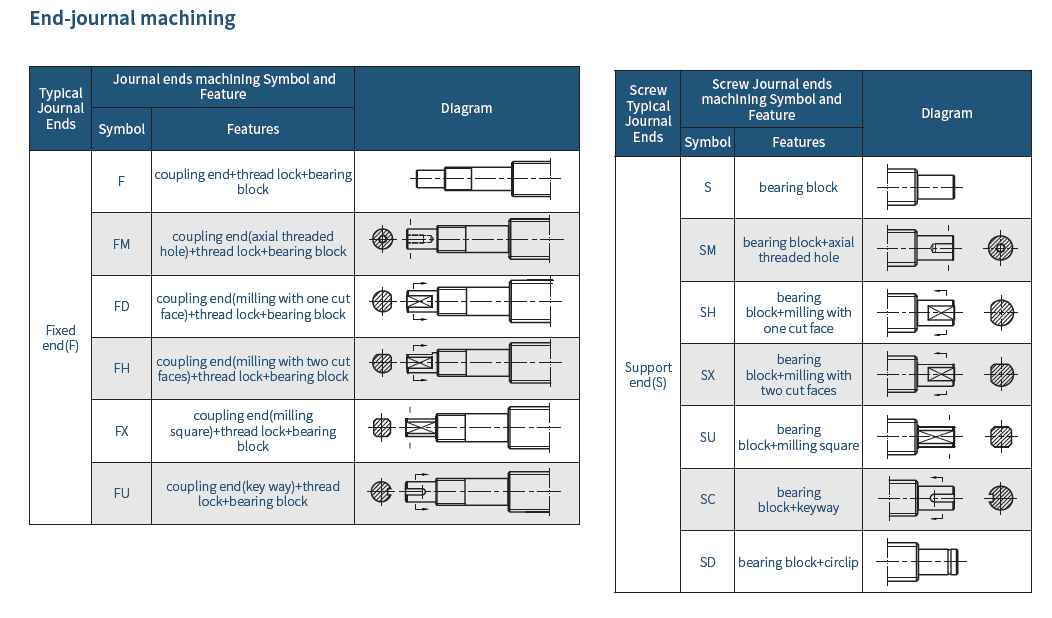

Thechnology of SCREWTECH end-journal maching enables to keep high accuracy of Ball Screws after we re-work. Please ask for end-journal maching to us. Precations of end-journal maching are as follows.

1. We recommend additional end-journal maching is done by SCREWTECH. We do not gurantee accuracy after re-works done by other than us.

2. When additional end-journal maching other than standard configuration in catalogue is requested, please send us drawing with end-journal profile on it.

3. Additional maching is not applied to the nut. Please design flange configuration according to our dimension table.

4. Lubrication-In Ball Screw use, lubricant should be applied on them.

Screwtech ball screw are in vacuum wrapping with anti-rust oil due to purpose for long term stock.

If you need specified lubricant, we will supply Ball Screw with lubricant you requested when requesting additional end-journal maching.

Since anti-rust oil is not lubricant, Ball screw should be washed off anti-rust oil when clean Kerosene and apply lubricant(Grease or lubricating oil).

Please check the lubricant condition every 2 or 3 months. If grease is contaminated, removed old grease, and replace with the new one.

ball nut falling by weight

If Ball Screw is not preloaded, Ball nut will fall down due to its own weight. Care must be taken.

Additional end-journal maching by customer

Additional end-journal maching done by customer is out of our guarantee, but in case of unavoidably conducting, please take caution regarding above precautions as well as following points.

Invasion of dust inside nut

Care must be taken regarding invasion of dust inside nut when additional end-journal maching.

If additional end-journal maching is being done to the shaft with ball nut, wrap the nut with vinyl, sealing up both ends and surely protect if from dust.

Nut removal

In case of nut removal, please use dummy shaft. We can supply dummy shaft with product if you request.

Make sure balls and screw shaft groove are meshing correctly and remove the nut slowly as well as re-assembling.

Cleaning after additional end-journal maching

After additional end-journal maching, ball screws should be washed dust off with clean Kerosene.

Applying lubrication

After additional end-journal maching, apply lubricant before using ball screw

Storage

After additional end-journal maching, surely conduct ant-rust treatment when ball screws are in long term stock.

To meet customer's request of quick delivery, SCREWTECH has specified model type in stock. The end-journal configuration is standardized and is possible to reduce numbers of design process by customer.

Precision Ball Screws which are accuracy C3, C5 and have machined Shaft end at fixed side in advance are available. Short delivery is available by machining supported end in accordance with customer`s request.

We produce economical Ball Screws which moves bi-directionally with one Shaft, and perform centering, precise positioning. There are Precision Ball Screws C3, C5 grade.