Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: 0602

Brand: SCREWTECH

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Construction Works, Other

Out-of-warranty Service: Online Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): United Kingdom, Spain, Romania, Kyrgyzstan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): United States, Thailand, Kazakhstan, Tajikistan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 3 Years

Core Components: Bearing, Motor

Processing Technology: Rolled Thread

Place Of Origin: China

Supply Ability & Additional Information

Packaging: wooden package or cartoon

Productivity: 2000pcs/month

Transportation: Ocean,Land,Air,Express

Place of Origin: SuZhou

Supply Ability: 2000pcs/month

Certificate: IATF16949

Port: ShangHai

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery

Product Description

6mm diameter 2mm pitch square Nut Ball Screw

With conventional Triangular and Trapezoidal Screw threads, reducing the axial play increases the rotational torque due to friction. SCREWTECH Ball Screws offer low friction with no axial play due the meticulous manufacturing methods employed. The use of double nuts can also further increase rigidity.

SCREWTECH Ball Screws are machined, assembled, and inspected using the technology of ultra-Precision Lead Screw and screw gauge machining, under the temperature-controlled environment. High precision and accurate positioning are ensured.

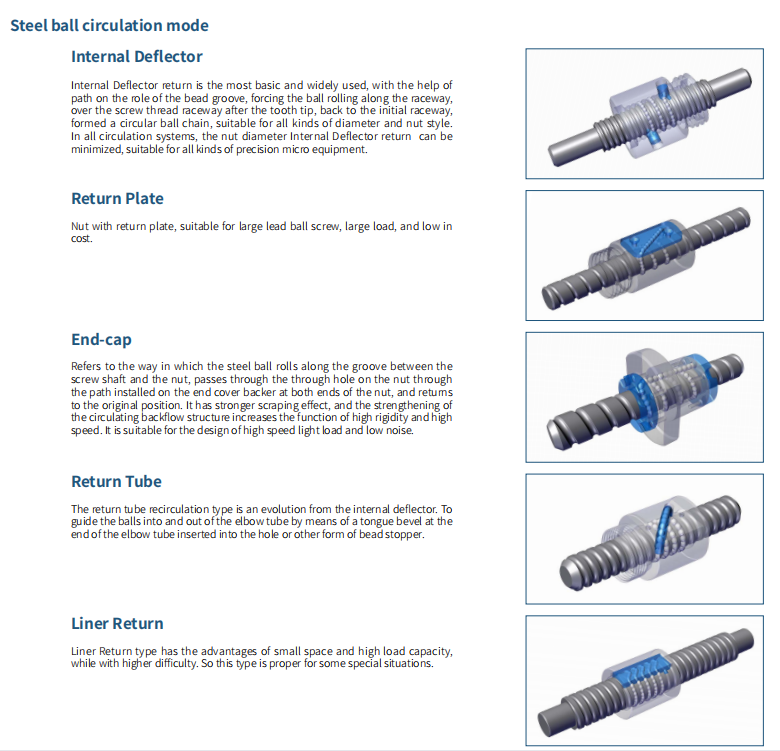

There are two commonly used circulation methods:

outer circulation and inner circulation. The ball that sometimes comes out of contact with the screw during the cycle is called the outer loop; the ball that always keeps in contact with the screw is called the inner loop. Each closed loop of the ball is called a row, and the number of leads contained in each closed loop of the ball is called the number of turns. Each nut of the inner loop Ball Screw pair has 2 rows, 3 rows, 4 rows, 5 rows, etc., each row has only one turn; each row of the outer loop has 1.5 turns, 2.5 turns and 3.5 turns.

1) Outer circulation: The outer circulation means that the balls return to the screw nut through the spiral groove or intubation on the outer surface of the nut after the circulation process is over. The return methods of the outer circulation Ball Screw Nut pair according to the ball circulation mainly include end cap type, intubation type and spiral groove type. Commonly used outer circulation method: end cap type; intubation type; spiral groove type. In the end cap type, a longitudinal hole is machined on the nut as a return passage for the balls. The cover plates at both ends of the nut have return ports for the balls, and the balls enter the return pipe to form a cycle. Intubation type, it uses an elbow as the return pipe. This structure has good manufacturability, but because the pipe protrudes from the nut body, the radial dimension is relatively large. Spiral groove type, it is a spiral groove milled on the outer circle of the nut, the two ends of the groove are drilled with through holes and tangent to the threaded raceway to form a return channel. This structure has a smaller radial size than the cannula structure, but Manufacturing is more complicated. The outer circulation structure and manufacturing process of the outer circulation ball screw are simple and widely used. The disadvantage is that it is difficult to smooth the joints of the raceways, which affects the stability of the ball raceways.

Screwtech is a professional manufacturer of Ball Screw,Lead Screw,Stepper Motor,Linear Guideway,AKD-Support for ball screw,Linear Bearing for more than 15 years

Features of our ball screw:

We can offer you products of high quality with economic price

We can design and produce customized products upon your requirement

We can produce the same size as HIWIN, TBI, PMI, and THK.

We have business rlations with clients both domestic and abroad.

With the high quality,good service as well as reasonable price,

we've obtained large numbers of customers from Europe, USA, Canada, Africa, Australia, Korea and so on.

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.