Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

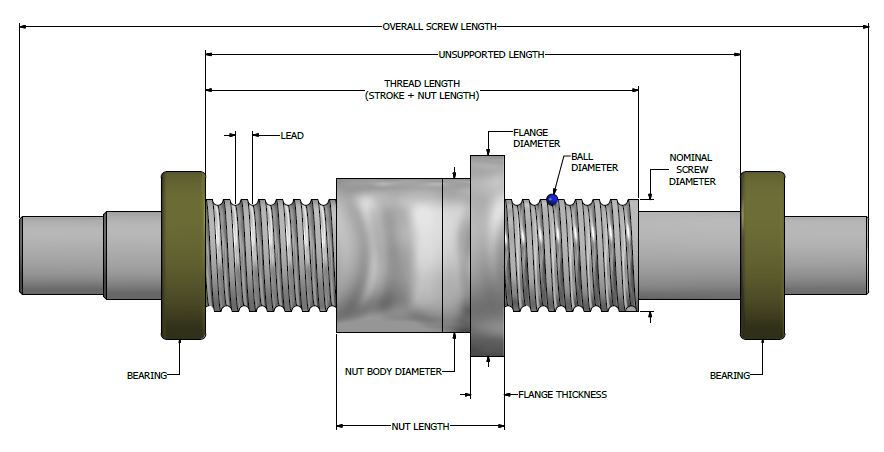

Ball Screw Design Resources When you need ball screw, we will introduce you to the specification process.In this article, you'll find some basic design information, explanatory terms, and useful diagrams.

The critical speed is the angular speed at which the screw (or nut) vibrates violently.Regardless of installation direction, the ball screw assembly must operate at its critical speed to avoid vibration, noise, and possible failure.

The size and position of the shaft imbalance, the length of the shaft, the diameter of the shaft and the type of Bearing support are the factors affecting the critical speed.Determination of ball screw life The service life of a ball screw assembly, usually measured in one million inches of travel.The workload rating is a major factor in determining the life of ball screws.Each application is unique;Duty cycle and environment also play a role. We encourage customers to consult with our engineering staff to discuss the specific requirements of their application.

The useful life of a ball screw assembly, usually given in terms of one million inches of travel. The operational load rating is a major determinate of ball screw life. Every application is unique; duty cycle and environment also have an effect. Customers are encouraged to consult with our engineering staff to discuss the specific requirements of their applications.

The amount of load to be moved is used to select the proper screw size.

Vertical load move: The nut load is equal to the weight to be moved plus the friction load.

Horizontal load move: The nut load is determined by multiplying the weight by the coefficient of friction.

Loads can also be measured with a spring scale or dynamometer, which is recommended for loads that are neither vertical or horizontal. The higher the load, the larger the size of the screw and nut is needed. The load capacity of a ball screw can be increased by increasing screw diameter, nut length, quantity of internal balls or ball diameter.

Lead error refers to the error in lead length per turn, compared to the basic lead specified. We manufacture Ground Ball Screws up to ANSI Class 2 or DIN/JIS Class 1 specification.

| Standard | Specification |

| ANSI C2, DIN/JIS C1 | 0.0002 in/ft or 5 μm/300mm |

| ANSI C5, DIN C3 | 0.0005 in/ft or 12 μm/300m |

| ANSI C7, DIN C5 | 0.001 in/ft or 25 μm/300mm |

| ANSI C8 | 0.006 in/ft or 150 μm/300mm |

The following chart indicates the relationship between various design specifications and operation parameters.

| INCREASE IN: | AFFECTS: | HOW: |

| Screw Length | Critical Speed | Decreases |

| Column Load | Decreases | |

| Screw Diameter | Critical Speed | Increases |

| Inertia | Increases | |

| Stiffness | Increases | |

| Load Capacity | Increases | |

| Column Load | Increases | |

| Lead | Torque | Increases |

| Load Capacity | Decreases | |

| Positioning Accuracy | Decreases | |

| Angular Velocity | Decreases | |

| Angular Velocity | Critical Speed | Decreases |

| Mounting Rigidity | Critical Speed | Increases |

| System Stiffness | Increases | |

| Load | Life | Decreases |

| Nut Length | Load Capacity | Increases |

| Stiffness | Increases | |

| No. of Balls | System Stiffness | Increases |

| Load Capacity | Increases | |

| Preload | Positioning Accuracy | Increases |

| System Stiffness | Increases | |

| Drag-Torque | Increases | |

| Ball Diameter | Life | Increases |

| Stiffness | Increases | |

| Load Capacity | Increases | |

| Lead | Increases |

Ball Screw Mounting Styles: Four standard mounting styles are available. Fixed ends offer the highest column load support and the highest resistance to vibration.

Fixed-Free

Fixed-Support

Support-Support

Fixed-Fixed

Ball Nut Styles: For standard ball nut styles are available. Internal and external returns can be applied to all styles.

Single Nut (1 piece)

Middle Flange Nut (1 piece)

Double Nut (2 pieces)

Flange to Flange Nut (2 pieces)

Your ball screw will be configured with the options you specify, and can be further customized for a complete turn-key solution that is quick and easy to install, saving you time and money. Customization options:

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.