Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Brand: WKT

Status: New

Warranty Period: 1.5 Years

Applicable Industry: Manufacturing Plant, Construction Works, Energy &Amp; Mining

Out-of-warranty Service: Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Russia, Morocco, Bangladesh

Showroom Location (in Which Countries Are There Sample Rooms Overseas): United Kingdom, Indonesia, Chile, Kyrgyzstan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor

Processing Technology: Milled Thread

Place Of Origin: China

Supply Ability & Additional Information

Packaging: Carton or wooden package

Productivity: 20000 pcs/ month

Transportation: Ocean,Land,Air

Place of Origin: Suzhou

Supply Ability: 20000 pcs/ month

Certificate: IATF16949

Port: Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDU,DDP,Express Delivery,DAF,DES

Product Description

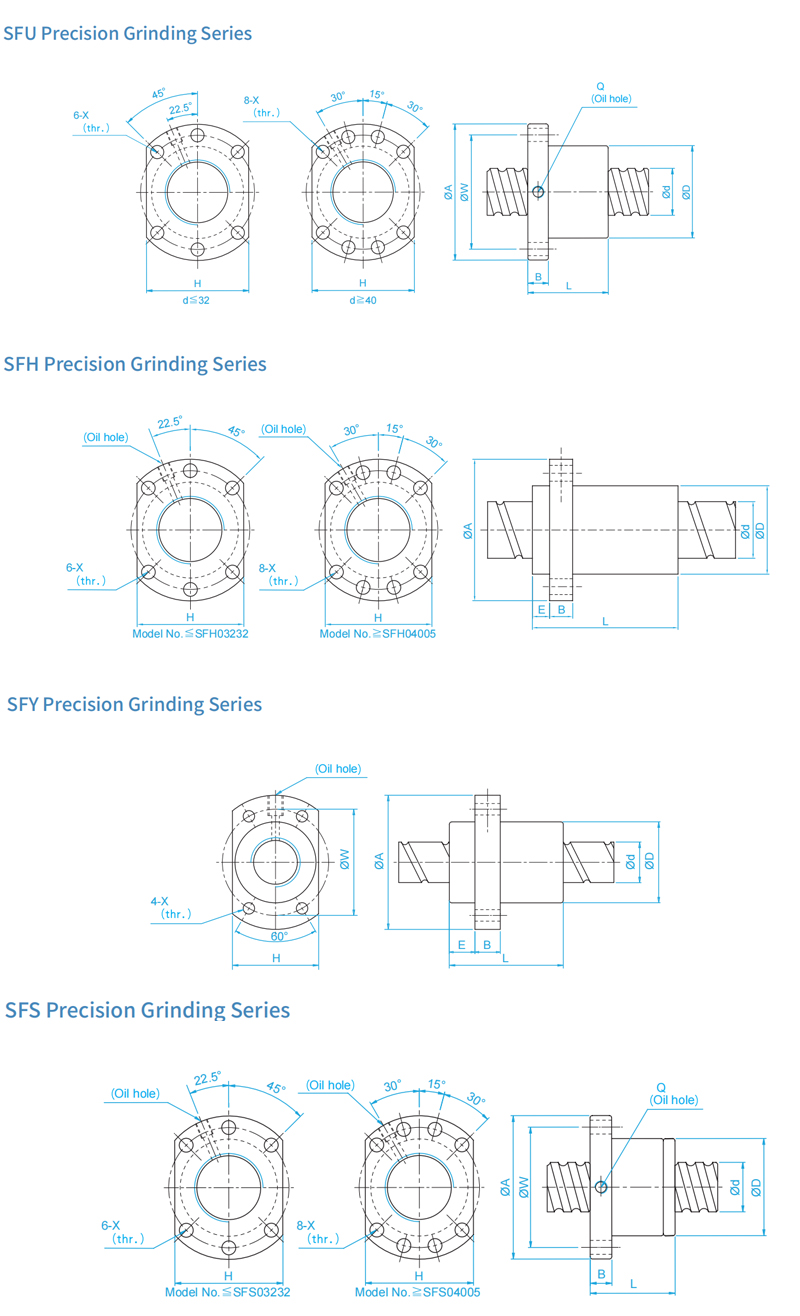

Double-Nut Ball Screw with High Precision

Ball screws are widely used in Machinery, especially along the feed axes of CNC machine tools. The Ball Screw has the characteristics of high precision, high rigidity, micro-feed and high-speed feed. However, the clearance between the balls and rollers can cause errors in the ball screw. To solve this problem, a Double Nut Ball Screw was developed. The preloading methods of the double nut ball screw mainly include positioning preloading and constant pressure preloading. Currently, the most common application of detent preload is to add a rigid washer between two nuts to create an axial relative offset between them, thereby creating an axial thrust. Different thicknesses of shims can be used to control the preload. The constant pressure preload is mainly due to the axial elastic tension generated by the spring installed between the two nuts. This is the axial preload of the ball screw, approximately constant. The positioning preload method was used in this study.

Product model selection

Product model selection

| Diameter | Pitch | Cycle mode | Nut Type | R/L thread | Raw Material | Surface Finishing | End Shaft Journal |

| 4 | 1 | I | F | R/L thread |

S1--SS304

S2--SS316

S3--SS316L

S4--SS440C

G--GCr15

|

CR--chromeplate

WS--tungsten disulfide coating

MS--molybdenum disulfide

BR--low temperature black chrome plating

BL--black coating

|

|

| K | R thread | ||||||

| 5 | 1 | I | F | R/L thread | |||

| 6 | 1 | I | F | R/L thread | |||

| A | R/L thread | ||||||

| S | R thread | ||||||

| K | F | R thread | |||||

| 2 | I | F | R/L thread | ||||

| A | R/L thread | ||||||

| 6 | E | F | R thread | ||||

| 8 | 1 | I | F | R/L thread | |||

| A | R thread | ||||||

| S | R thread | ||||||

| C | R/L thread | ||||||

| K | F | R/L thread | |||||

| 2 | I | F | R/L thread | ||||

| A | R thread | ||||||

| S | R/L thread | ||||||

| K | F | R/L thread | |||||

| 2.5 | I | F | R thread | ||||

| A | R thread | ||||||

| 4 | U | F | R thread | ||||

| P | F | R/L thread | |||||

| 5 | P | F | R/L thread | ||||

| 8 | P | F | R thread | ||||

| E | F | R/L thread | |||||

| 10 | 2 | I | F | R/L thread | |||

| A | R/L thread | ||||||

| K | F | R/L thread | |||||

| 3 | I | F | R/L thread | ||||

| 4 | I | F | R/L thread | ||||

| A | R thread | ||||||

| W | F | R thread | |||||

| 10 | E | F | R/L thread | ||||

| 12 | 1 | I | F | R/L thread | |||

| 2 | I | F | R/L thread | ||||

| A | R/L thread | ||||||

| 3 | I | F | R/L thread | ||||

| 4 | I | F | R/L thread | ||||

| A | R thread | ||||||

| 5 | I | F | R thread | ||||

| A | R thread | ||||||

| C | R thread | ||||||

| E | F | R/L thread | |||||

| 8 | P | F | R thread | ||||

| 10 | W | F | R/L thread | ||||

| 14 | 2 | I | F | R/L thread | |||

| 3 | I | F | R/L thread | ||||

| 4 | I | F | R/L thread | ||||

| 5 | I | F | R/L thread | ||||

| 16 | 2 | I | F | R/L thread | |||

| 4 | U | F | R/L thread | ||||

| 5 | I | F | R/L thread | ||||

| U | F | R/L thread | |||||

| 10 | I | F | R/L thread | ||||

| U | F | R/L thread | |||||

| 16 | E | F | R thread | ||||

| 20 | 4 | U | F | R/L thread | |||

| 5 | I | F | R/L thread | ||||

| U | F | R/L thread | |||||

| 10 | U | F | R/L thread | ||||

| 25 | 4 | U | F | R/L thread | |||

| 5 | I | F | R/L thread | ||||

| U | F | R/L thread | |||||

| 6 | U | F | R/L thread | ||||

| 10 | I | F | R/L thread |

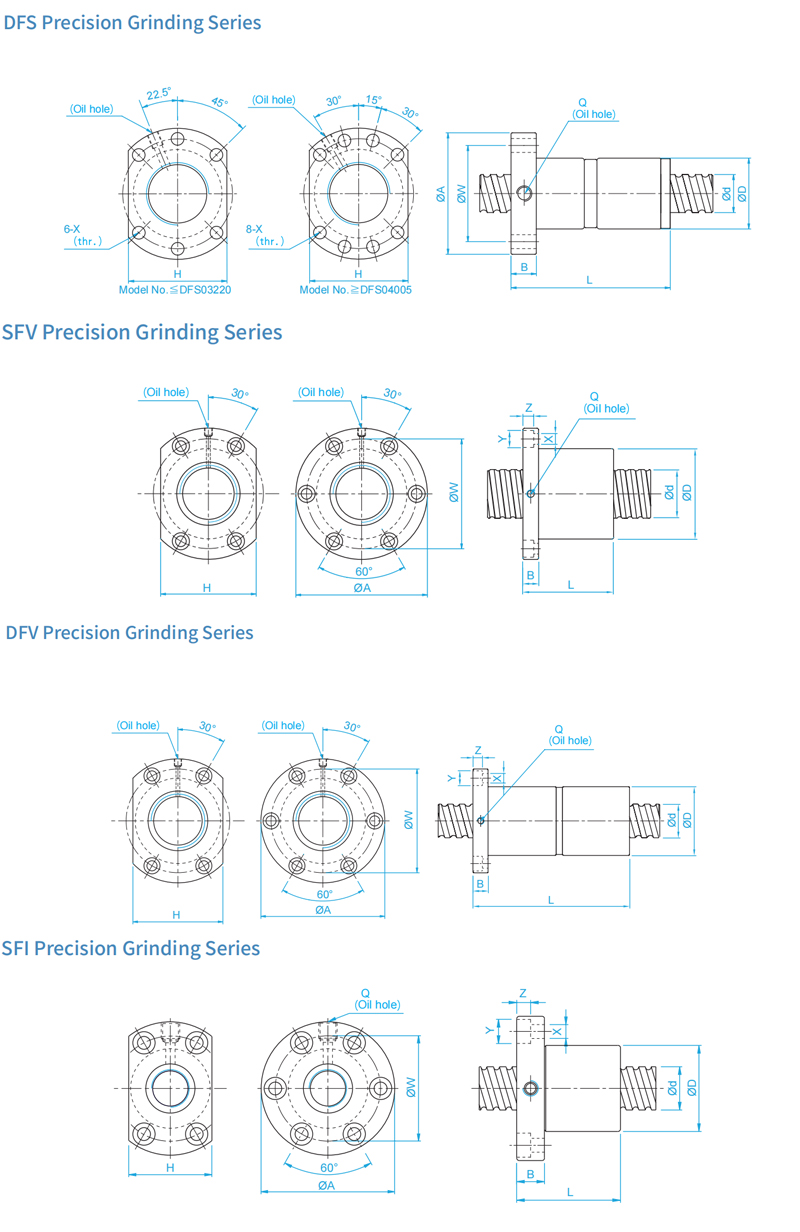

Steel ball circulation mode

| Round Internal Deflector | Return Tube | Liner Return | Return Plate | End Cap | Intubation |

|

I |

U | K | P | E | W |

|

|

|

|

|

|

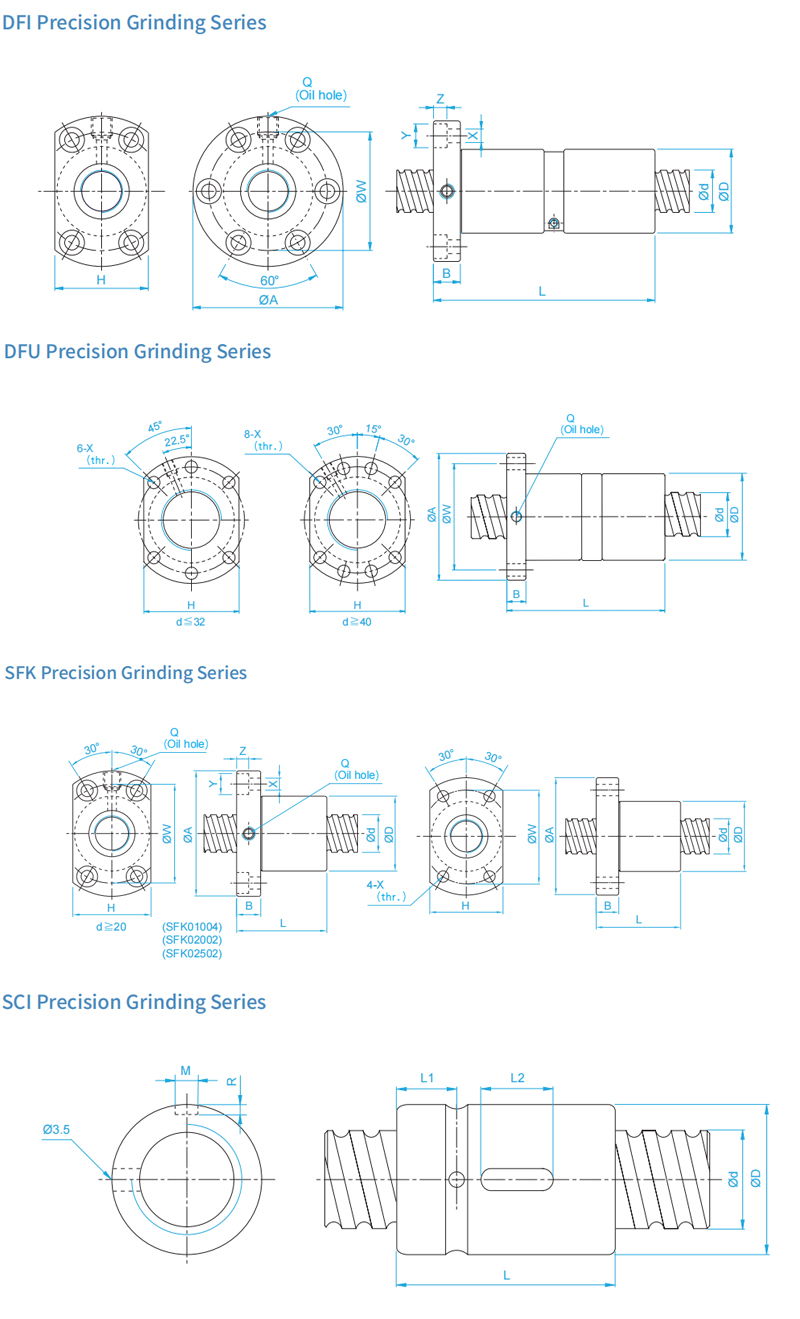

Common nut shape

| Round Nut with Flange | Round Nut with Thread | Square Nut | Cylinder Nut with Key | Square or Round Nut with Trunnion | Others |

|

F |

A | S | C | B |

|

|

|

|

|

|

|

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.