Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Supply Ability & Additional Information

Packaging: Carton or wooden package

Productivity: 20000 pcs/ month

Transportation: Ocean,Land,Air

Place of Origin: Suzhou

Supply Ability: 20000 pcs/ month

Certificate: IATF16949

Port: Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDU,DDP,Express Delivery,DAF,DES

Product Description

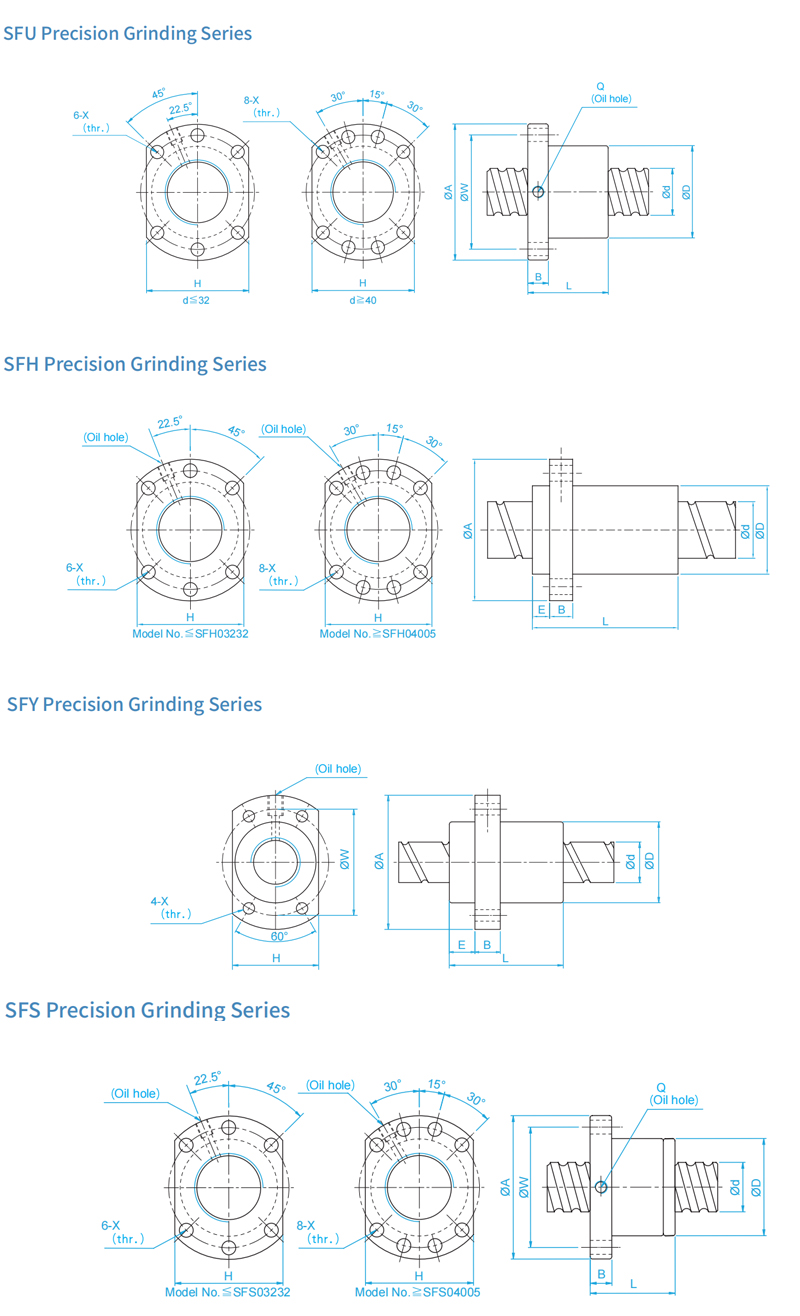

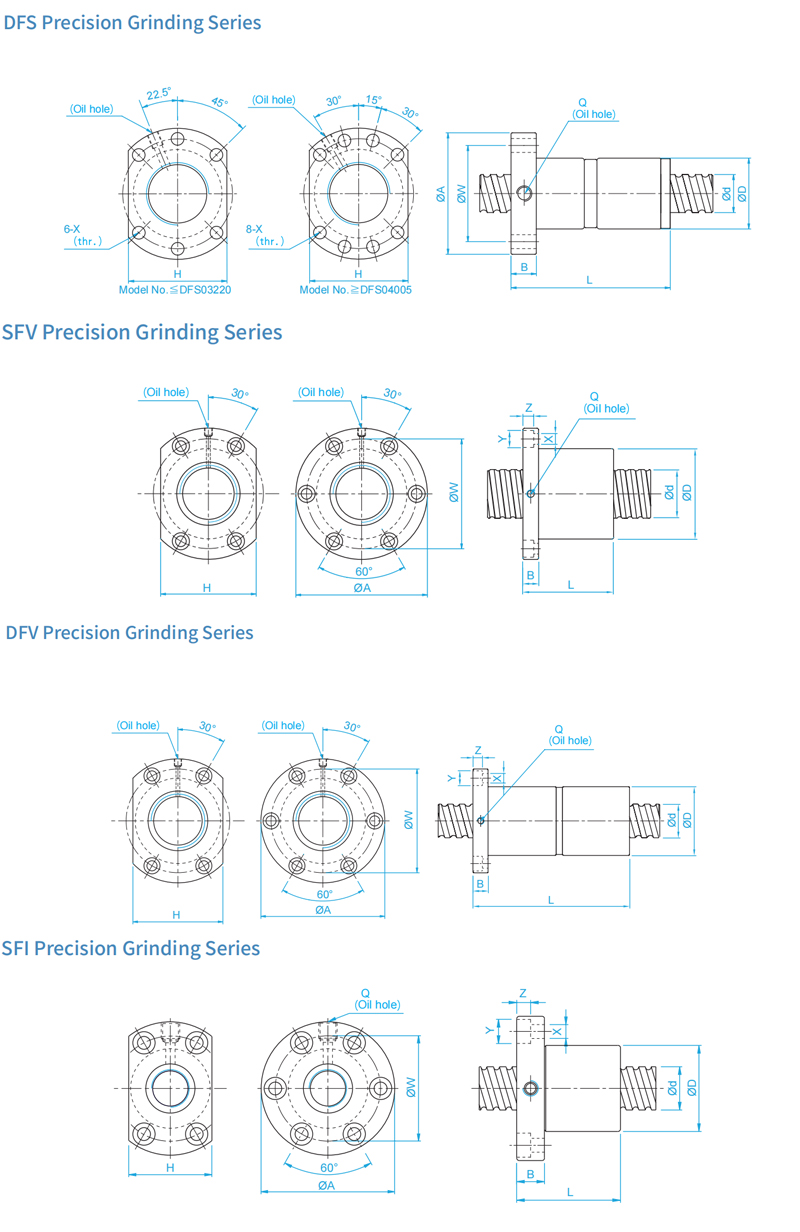

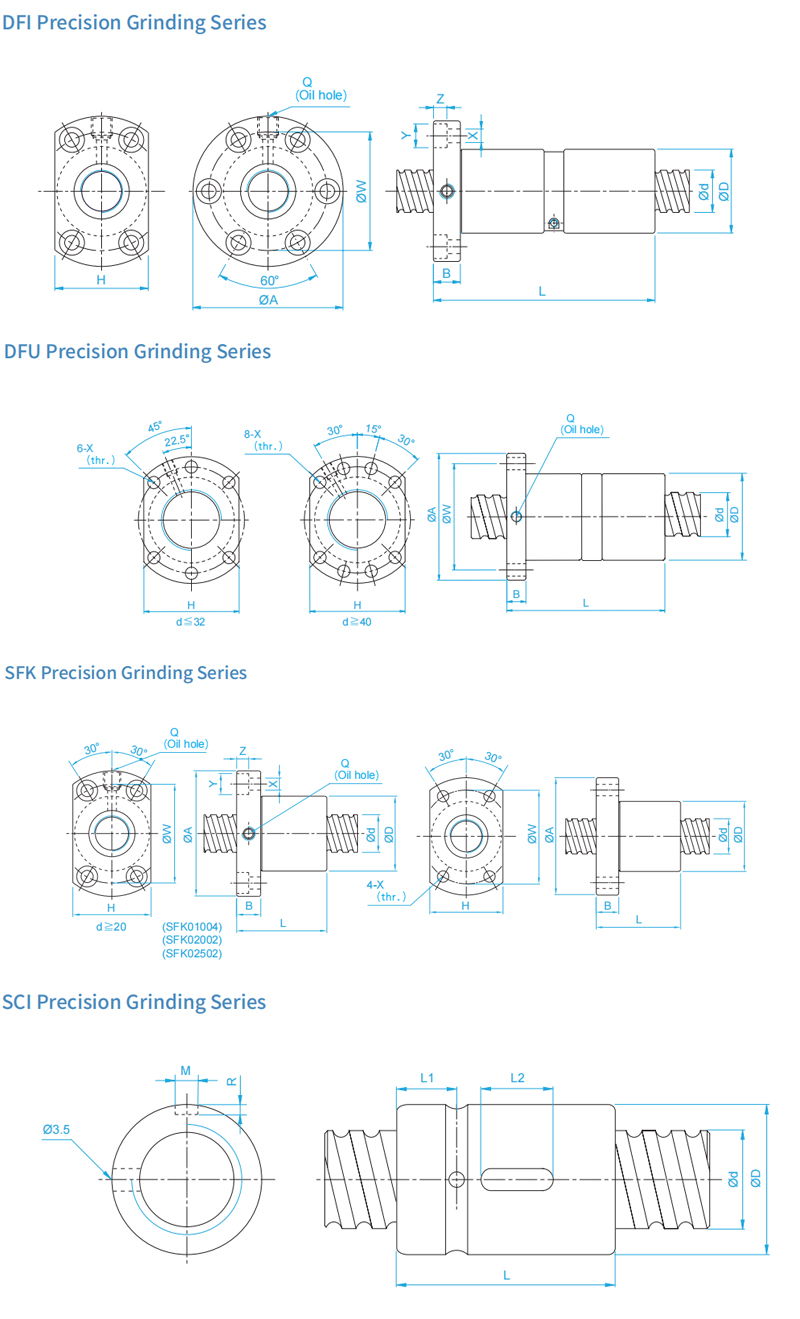

SCREWTECH is the ideal CNC Ball Screw manufacturer and supplier We offer a variety of options at great prices to help you get creative. All Ball Screw repairs are quality guaranteed. We are the original Chinese factory for ball screw prices. If you have any questions, please feel free to contact us. 1.Ball screw description: A ball screw is a product that converts rotary motion into Linear Motion, or converts linear motion into rotary motion. A ball screw consists of a screw, a nut, balls and a reversing device. Its function is to turn rotary motion into linear motion, which is the further extension and development of ball screw. 2.The difference between a Lead Screw and a ball screw The basic difference between a lead screw and a ball screw is that a ball screw uses a ball Bearing to eliminate friction between the nut and the lead screw, whereas a lead screw does not. The lead screw uses a deeper helical thread and mating nut, usually made of polymer composite or bronze. High speed feed: 3. Application of ball screw Note: Other sizes,and nut shapes are available upon request !

High positioning accuracy: the accuracy meets the requirements of JIS C3. Acceleration: Over 1.0 g (9.8 m/sec2) to avoid wasting time between acceleration and deceleration.

Heavy stiffness:

Optimized screw shape and structure design. Overload: Multi-load ball distribution design. Low Vibration Noise: Noise reduction with optimal slenderness ratio and high-speed cycling.

Constant temperature:

Efficient heat transfer can suppress thermal deformation and improve stability. Environmental protection: optional

The self-lubricating function can reduce the consumption of lubricating oil and reduce the pollution of lubricating oil waste to the environment. It also solves the problem of uneven thickening of lubricating oil caused by the deformation of the oil film in the spiral path.

Company Overview

Description:

Ball screw pair, also known as ball screw pair, ball screw pair. It is composed of two sets of screws and nuts. It is the most accurate and most commonly used transmission device in transmission machinery.

(1) External circulation: The external circulation is that the balls return to the screw and nut through the spiral groove or cannula on the outer surface of the nut and re-enter the circulation after the end of the circulation process. The return methods of the external circulation ball screw nut pair according to the ball circulation mainly include end cap type, intubation type and spiral groove type.

For the end cap type, a longitudinal hole is machined on the nut as a return passage for the balls. The cover plates at both ends of the nut are provided with return openings for the balls, from which the balls enter the return pipe to form a circulation. Intubation type, which uses elbows as return pipes, this structure has good manufacturability, but because the pipes protrude from the outside of the nut, the radial size is large. Spiral groove type, it mills a spiral groove on the outer circle of the nut, and drills through holes at both ends of the groove and is tangent to the threaded raceway to form a return channel. This structure is smaller than the intubation structure in radial size, but Manufacturing is more complicated. The outer circulation ball screw has a simple structure and manufacturing process and is widely used. The disadvantage is that it is difficult to smooth the seam of the raceway, which affects the stability of the ball raceway.

(2) Inner circulation: Inner circulation adopts reverser to realize ball circulation, and there are two types of reverser. Cylindrical convex key reverser, its cylindrical part is embedded in the nut, and the end is provided with a reverse groove. The reverse groove is positioned by the cylindrical outer surface and the round key at the upper end to ensure alignment with the thread raceway direction. The oblate insert reverser, the reverser is a general round head flat key insert, the insert is embedded in the groove of the nut, and the end is provided with a reverse groove, which is positioned with the outer contour of the insert. Comparing the two reversers, the latter is smaller in size, thereby reducing the radial dimension of the nut and shortening the axial dimension. However, the dimensional accuracy of the outer contour of the reverser and the groove on the nut is relatively high.

We Screwtech is a professional manufacturer of Ball Screw,Lead Screw,Stepper Motor,Linear Guideway,AKD-Support for ball screw,Linear Bearing for more than 15 years

1. We can offer you products of high quality with economic price

2. We can design and produce customized products upon your requirement

3. We can produce the same size as HIWIN, TBI, PMI, and THK.

Our Business Extent

We have business rlations with clients both domestic and abroad.

With the high quality,good service as well as reasonable price,

we've obtained large numbers of customers from Europe, USA, Canada, Africa, Australia, Korea and so on.

Welcome to inquiry

If you have any related inquiry,please feel free to contact us.

www.screw-tech.com

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.